OPTICS AND OPTICAL MEASUREMENT INSTRUMENTS

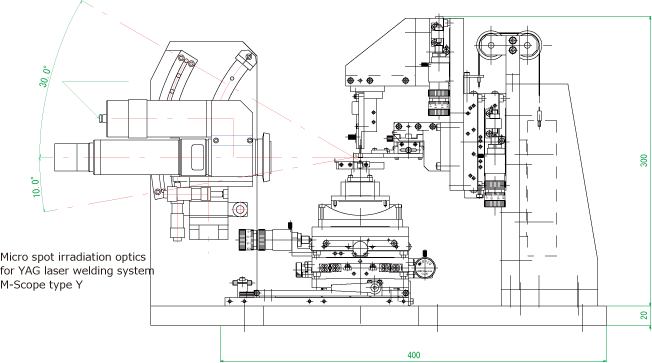

MICRO SPOT IRRADIATION OPTICS FOR YAG LASER WELDING M-Scope type Y

PRODUCT OVERVIEW

M-Scope type Y is micro spot irradiation optics for YAG laser welding system, best for assembly by micro spot welding of various optical modules, precision component, etc.

As coaxial observation camera and illumination system are equipped, easy and accurate welding process can be realized by observing welding position of precision component directly.

Furthermore, as double beam simultaneous irradiation system is adopted, high accuracy micro welding is realized.

FEATURE

- Easy and accurate welding by direct observation of welding position

- As coaxial observation camera and illumination system are equipped, easy and accurate welding process can be realized by observing welding position of precision component directly. Operator can set the welding position easily, and shot the welding beam accurately.

- Double beam simultaneous irradiation system

- Double beam simultaneous irradiation system, optical beam bifurcation mechanism, is equipped. Through this mechanism, laser beam introduced by single fiber is bifurcated into equally divided double beams in M-Scope type Y. Equally divided double beams are focused on the same plane through the same focusing lens. This system realizes two beam simultaneous and well balanced welding, and contributes to make welding declination minimize and realize high accuracy micro welding.

- Single beam irradiation model is also prepared.

- Prepared two types of irradiation spot magnification

- 1:1 type : irradiate the same spot size of input optical fiber core diameter

- 1:2 type : irradiate half size of input optical fiber core diameter

APPLICATION

- Fixation by YAG welding of various optical modules after optical alignment

- Micro welding of micro spring for HDD unit

- Laser marking

- High accuracy micro welding for general precision components

SUMMARY OF SPECIFICATION

MAIN SPECIFICATION OF THE OPTICS

| Welding beam irradiation method | Double beam simultaneous irradiation system (Single beam irradiation system is also prepared) |

|---|---|

| Irradiation spot magnification ratio | 1:1 (standard : irrdaiate the same spot size of input optical fiber core diameter) 1:2 (option : irradiate half size of input optical fiber core diameter) |

| Irradiation spot diameter (nugget diameter) |

approx. 400umφ (standard, input fiber diameter:400umφ, Magnification:1:1) approx. 200umφ (option, input fiber diameter:200umφ, Magnification:1:2) |

| Optical magnification of observation | approx. 1× |

| View of observation | approx. 7mm×5.2mm(using 1/1.8 inch CMOS camera) |

| Aberration correction wavelength | 1.06um (guidance light wavelength : 633nm) |

| Working Distance | approx. 87.7mm |

| Illumination | LED ring illumination |

| Fiber connector | D-80 fit connector for fiber input |

COMPONENT

STANDARD COMPONENT

- M-Scope type Y (optics unit, LED ring illumination, CMOS detector for observation) : 1set

OPTION

- Personal Computer for image monitor

TECHNICAL INFORMATION

MANUAL ALIGHMENT AND YAG WELDING SYSTEM FOR OPTICAL MODULE ASSEMBLY USING M-Scope type Y